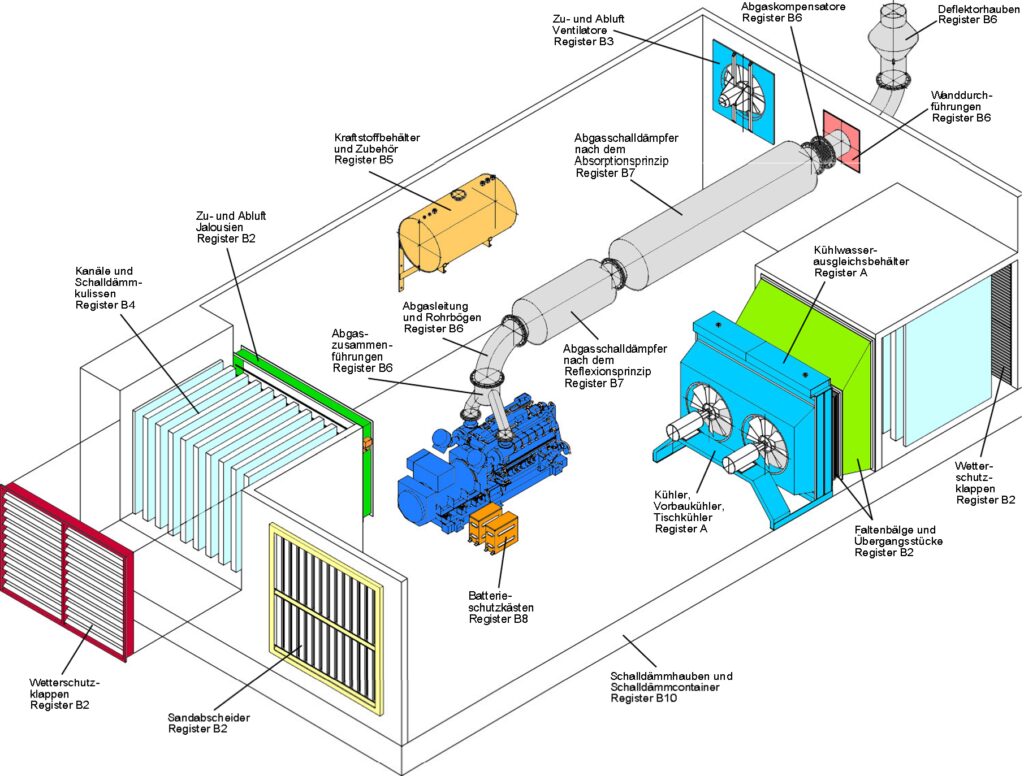

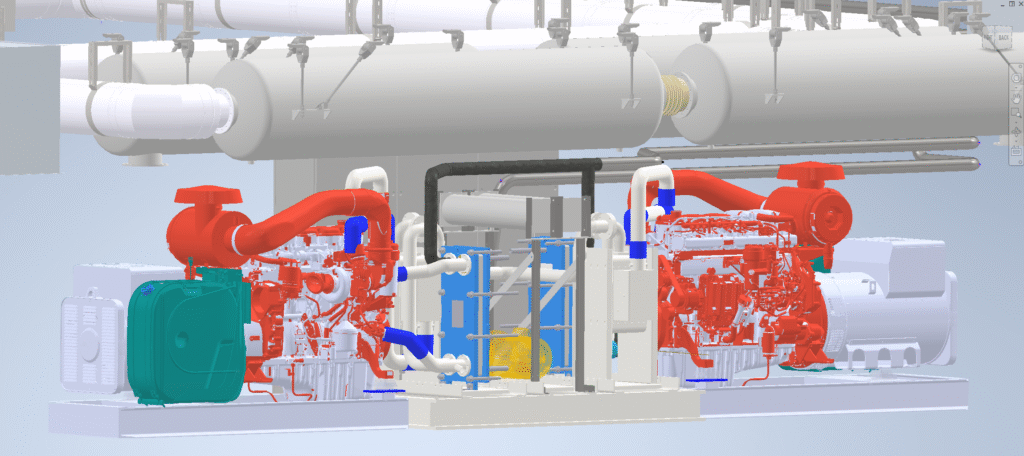

Radiators

Our radiators are designed for your specific application.

We take into account your installation dimensions, the environment, the desired additional head and noise requirements.

Numerous designs are possible; please contact us to discuss all options.

Material selection:

- For dusty environments, we can use larger fin spacings and smooth fins.

- For marine environments, we can tin the cooling blocks and galvanize the non-water-bearing steel parts.

- Inspections: An inspection by DNV/ Loyds is possible.

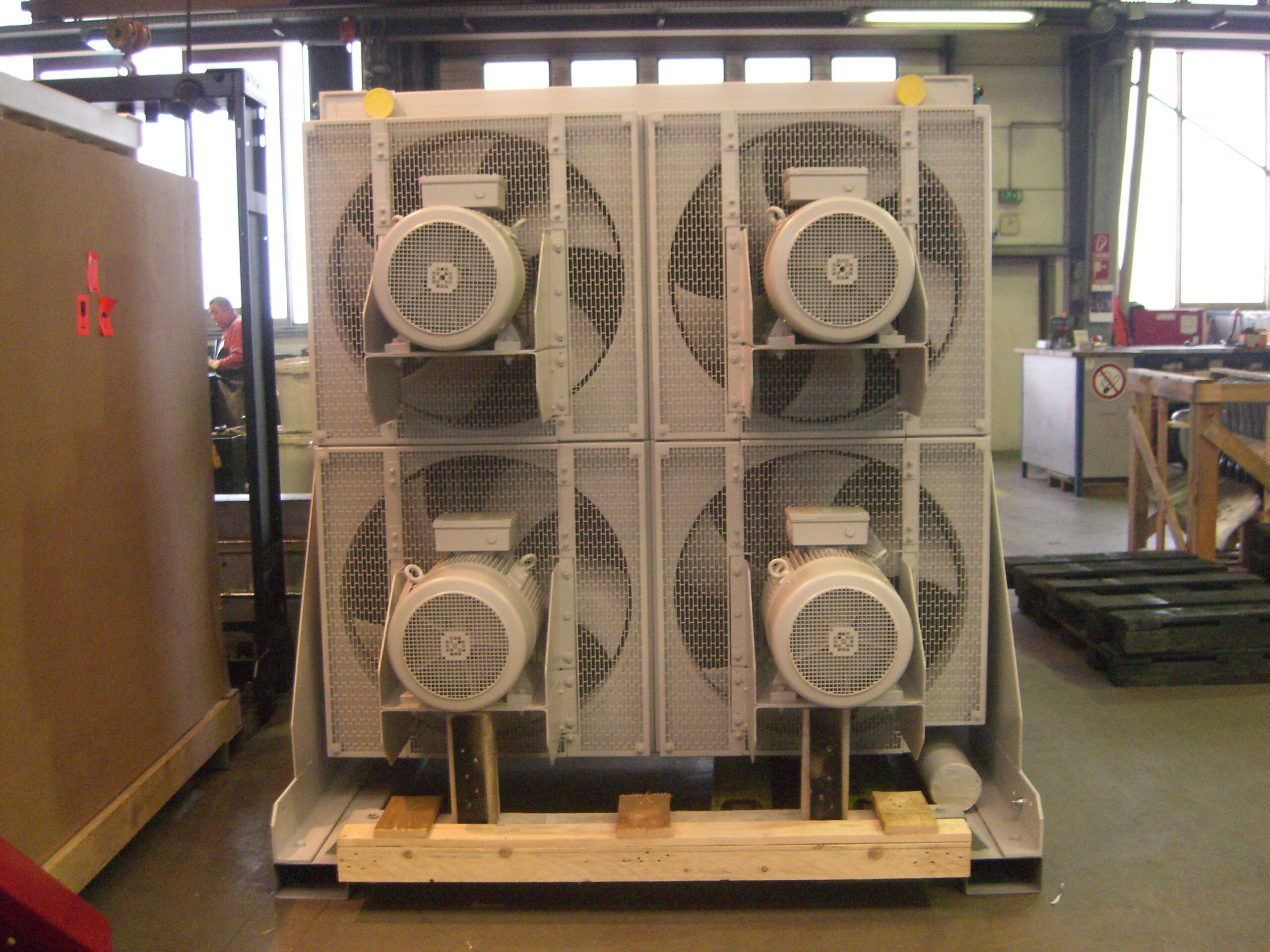

- Larger radiators can be supplied in modular form. If one module is damaged, only that module needs to be replaced. However, the modular design does have a greater installation height.

- Depending on the installation options, the circuits can be placed next to each other or in front of each other.

- ATEX version: E-motors, level switches and impellers can be selected from anti-static material.

- Plate & Bar aluminum coolers, with or without alucoating.

Executions

- Radiator unit:

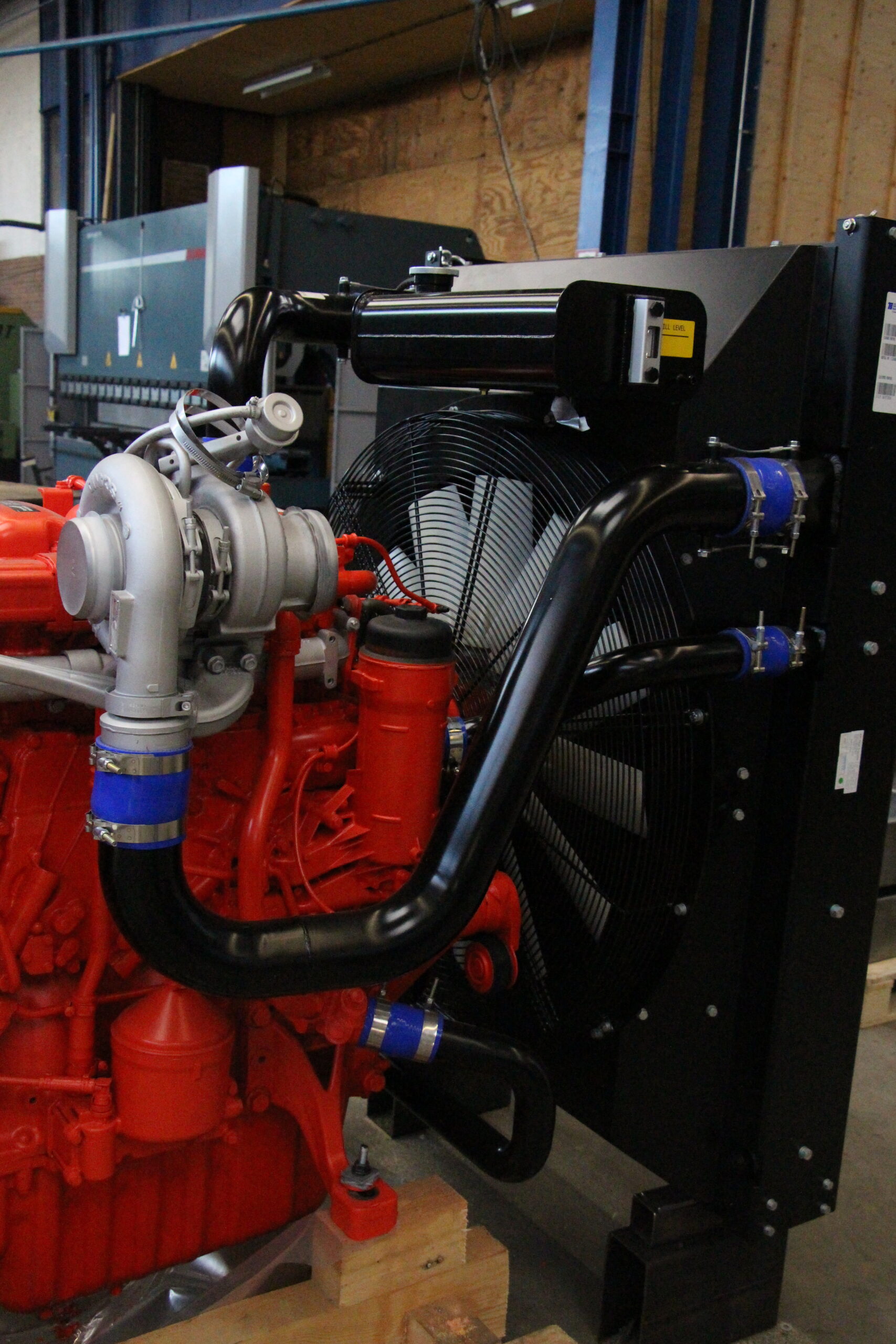

Fans driven by E-motor or Hydraulic motor. - Radiator with hood:

Impeller on the diesel engine, often using the standard impeller and transmission ratio of the diesel engine manufacturer. The fan curve is therefore important for a good offer. - Radiator with free shaft end:

Radiator with the impeller shaft mounted on the radiator with a free shaft end. Pulley driven by the diesel engine.

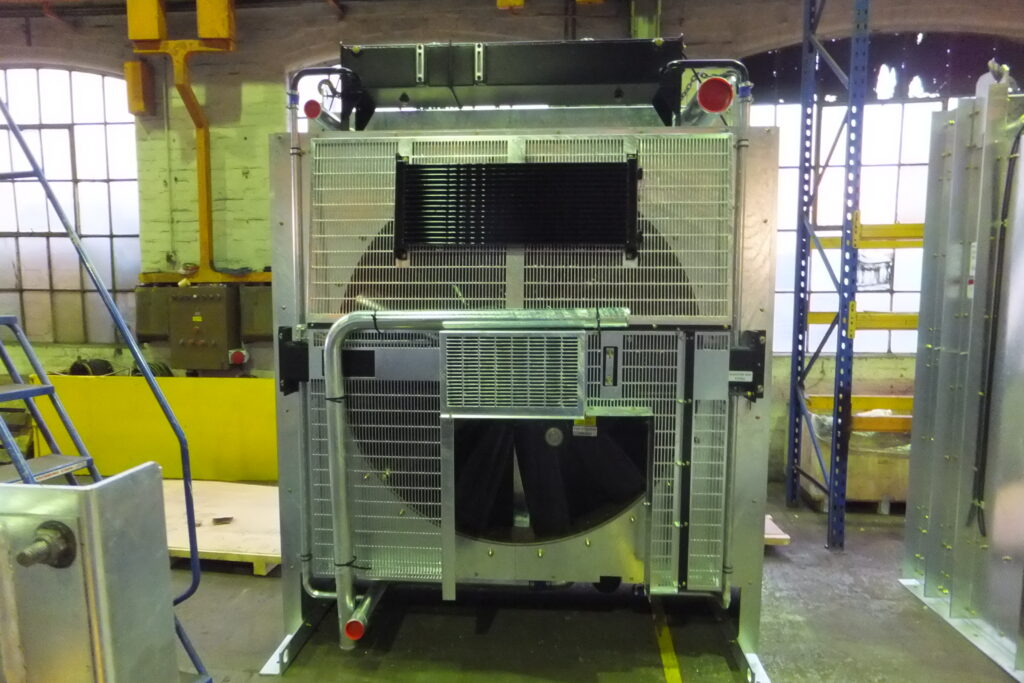

The advantage of the radiator unit with free shaft end is that the speed can be chosen independently. - Radiator panels for installation in containers:

If the radiator is installed in a container, the field of application is usually wide; one often wants to be able to use the container worldwide!

High ambient temperatures, limited space, use in both 50 and 60Hz countries, and perhaps also a noise requirement. In addition to the radiator, we can also supply the fans in the roof. It is important to know how the fans are installed in your application.

Information required for a quotation

- Motor datasheet

- Environmental situation

- Ambient temperature

- Installation dimensions

- Duct allowance

- Desired execution

Related products & services:

Engineering

Pipework