Resonance principle

AR/ADR type exhaust gas silencers operate on the resonance principle.

Operating principle:

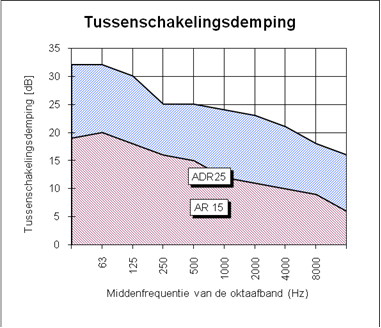

The high damping values at low frequencies are achieved by dividing the silencer into separate compartments interconnected by resonance pipes. Optimal damping is achieved, especially in the range of the ignition frequencies.

Execution:

The housing of the exhaust gas silencer consists of a steel plate cylinder with a curved bottom and connecting pipes with/without connecting flanges. At the deepest point of the exhaust gas silencer, a socket with a plug is fitted to create a connection for condensate drainage.

Installation:

AR/ADR type exhaust gas silencers can be mounted horizontally and vertically. However, attention must be paid to the expansion of the exhaust gas line,

as well as the transmission of engine vibrations and sound emission through the wall of the exhaust gas silencer.

Insulation:

Exhaust gas silencers, type AR/ADR, according to the resonance principle, do not contain any internal insulation material and therefore become as hot as the uninsulated exhaust gas line. We therefore strongly recommend that you apply on-site insulation for heat and sound radiation.

.

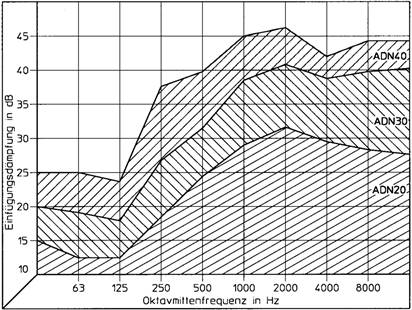

Absorption principle

Operating principle:

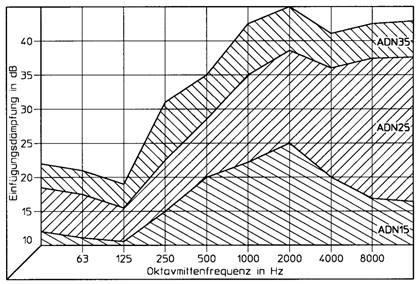

ADN type exhaust gas silencers operate on the absorption principle. The exhaust gases are passed through a flow channel made of perforated steel plate. Due to this straight-line flow, the flow resistance is low. Long-fiber, mechanically and thermally particularly friction-resistant, sound-absorbing material, which is installed between the flow channel and the silencer housing, destroys the sound energy.

The flow velocity in the area of the perforated steel plates must not exceed 45 m/s to 50 m/s (higher exhaust gas velocities on request).

Execution:

The exhaust gas jacket consists of a steel plate cylinder with a curved bottom and pipe ends of your choice (with or without connecting flanges).

At the lowest point of the exhaust gas silencer, a socket with a plug is fitted to allow a connection for condensate drainage.

Installation:

ADN type exhaust gas silencers can be mounted horizontally and vertically.

Attention must be paid to the expansion of the exhaust gas line and also to the transmission of engine vibrations and jacket noise.

Calculation data:

In order to process your request, we need the following information:

- Engine manufacturer and type.

- Engine power and engine speed

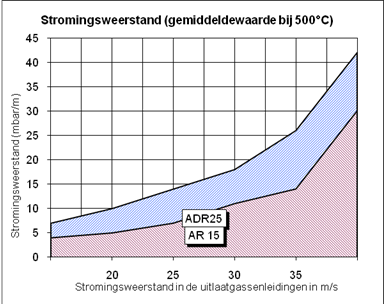

- Exhaust gas quantity and permitted pressure loss

- Exhaust gas temperature

- Connection diameter to the engine

- Required sound pressure reduction or,

- The dB(a) sound pressure to be achieved, stating the distance from the gas outlet opening, environmental factors including source noise.

Note: Radial exhaust gas inlet and/or outlet increase the flow resistance

Combined silencer with resonance and absorption part

ARN type exhaust gas silencers operate on the resonance and absorption principle.

A combined exhaust gas silencer combines the advantages of both systems and therefore provides very good sound-damping properties over the entire frequency spectrum.

Execution:

The exhaust gas silencer body consists of the steel plate cylinder with a curved bottom and welded ends with or without welded flanges.

The resonance section is internally without insulation material and will therefore become as hot as the uninsulated exhaust gas line.

We therefore strongly recommend that you insulate the resonance section on site due to heat and jacket noise radiation.

A socket with a plug is fitted on the exhaust gas silencer to allow condensate to be drained.

Installation:

Exhaust gas silencers can be mounted both horizontally and vertically, by specifying this in any request and/or order.

Attention must be paid to the expansion of the exhaust gas line and also to the transmission of engine vibrations and radiation of jacket noise.

Calculation data:

In order to process your request, we need the following information:

- Engine manufacturer and type.

- Engine power and engine speed

- Exhaust gas quantity / permitted pressure loss

- Exhaust gas temperature

- Nominal diameter of the exhaust gas connection on the engine

- Required sound pressure reduction

- The dB(a) sound pressure to be achieved, stating the distance from the gas outlet opening, environmental factors including source noise.

- Indication of source noise, if possible with the sound spectrum of the exhaust gas noise.

note:

radial exhaust gas inlet and/or outlet increase the flow resistance. It is of course also possible to make the “inside” of the resonance section larger than the inlet and outlet of the exhaust gas silencer in order to keep the back pressure as low as possible.