Dry coolers

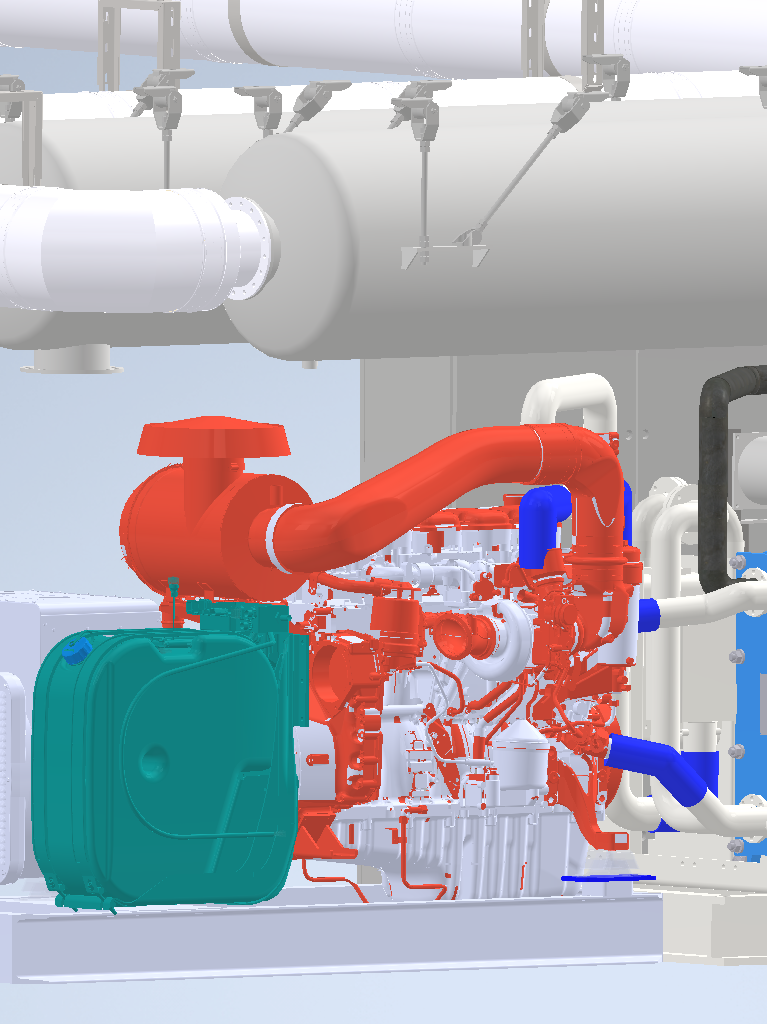

Table coolers can be used for both direct and indirect cooling.

For application in an indirect cooling system, please read more about the indirect cooling system.

Table coolers are being used more and more frequently.

An important advantage is that a low sound pressure level can be achieved with low-speed fans. This is important in built-up environments where not too much noise may be produced.

Another advantage is that they can be placed remotely and therefore do not have to be placed in a cramped machine room.

Numerous designs are possible!

Executions

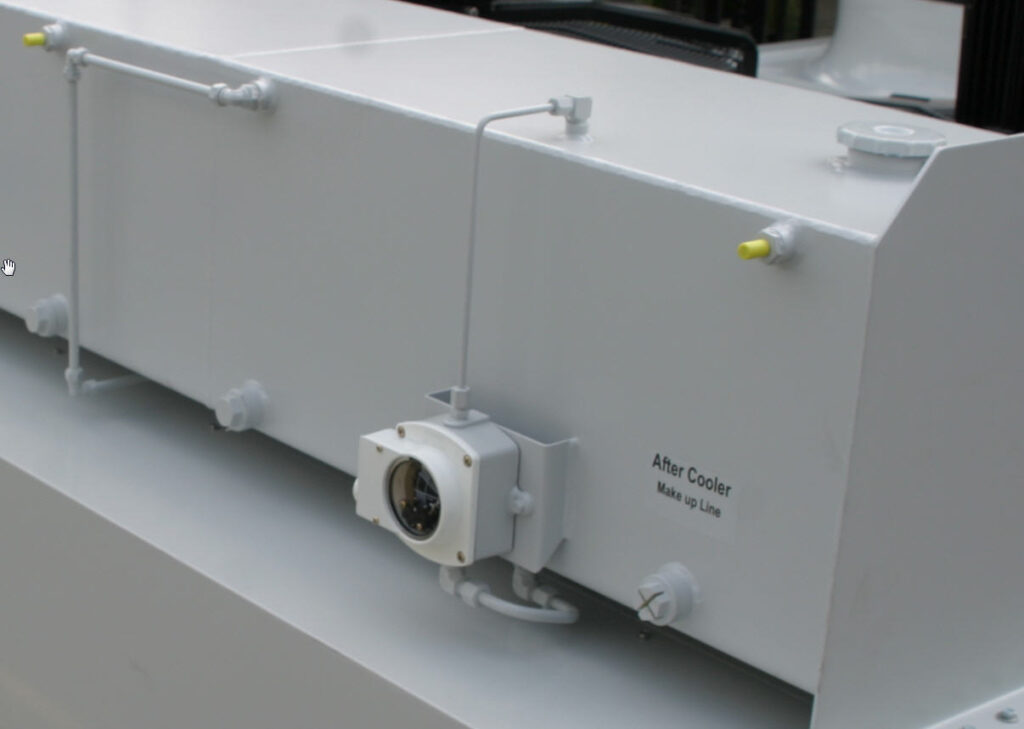

Table coolers are also suitable for use with high working pressure, for example with gas engines.

Table coolers can be dimensioned in various ways. The width is usually fixed (2200mm), the length can easily be adjusted to your power and noise requirements.

Leg lengths (height) can be adjusted to your wishes. Detachable legs make transport in a container possible. We can stack coolers in containers to save on transport costs for large orders. This ensures you the most competitive price for the complete delivery!

Material choice

Our table coolers are designed for outdoor installation, for example on the roof or on a container. The housing is made of galvanized steel, coated with UV-resistant powder coating.

Depending on the application, we supply table coolers in various material versions:

- Copper/brass

- Copper/aluminum

- Aluminum Manganese (AlMg)

- Stainless steel/aluminum

For applications in an environment with sea air or ammonia in the air, the fins can be provided with a Blygold coating in order to increase the corrosion resistance.

Offshore

For “off-shore” installations we use other coolers with a reinforced supporting structure, galvanized housing and tinned copper fins.

Dusty environment

For installations in dusty environments, we can adjust the fin distance and opt for straight, smooth fins without incisions. This ensures good operation of the cooler under the most difficult conditions

Required information for a table cooler quote

- Motor datasheet

- Environmental situation

- Ambient temperature

- Installation dimensions

- Duct allowance

- Desired execution

Related Products and Services

Engineering

Remote cooling kit